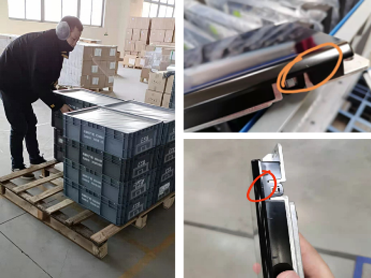

时间 Time:2019-7-27

地点 Location:Benz(Beijing )

产品 Product:H247车灯 lamp

车型 Model:GLB247

数量 Quantity:530台

作业内容 Work content: 车灯异物清洁

lamp cleaning of foreign bodies

①戴好手套,防止对产品造成损伤 wear gloves to prevent damage to the product;

②产品拿取要求轻拿轻放 Product take requirements light take light;

③大灯表面有异物,可喷上酒精用百洁布轻轻擦拭 The surface of the headlamp has a foreign body, can be sprayed with alcohol with

clean cloth gently wipe;

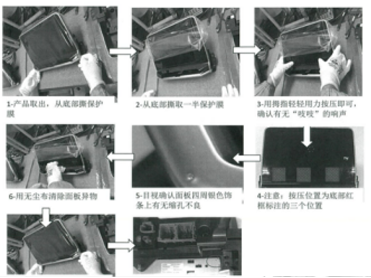

时间 Time:2020-11-27

地点 Location:安徽蔚来 NIO

产品 Product:ES8仪表 Cluster

车型 Model:ES8

数量 Quantity:1030台

作业内容 Work content: ES8仪表注塑不良分选。

ES8 cluster for poor injection molding sorting

①产品从箱子取出,检查后需放回原箱子中 The product is taken out of the box and should be put back into the original box after

inspection;

②产品拿取要求轻拿轻放 Product take requirements light take light;

时间 Time:2020-11-27

产品 Product:降燥模块 dryness control module

数量 Quantity:3000台

地点 Location:广汽三菱 Mitsubishi

车型 Model:奕歌 Eclipse

作业内容 Work content: 降燥模块尺寸不良分选 Bad size sorting of dryness control module

①产品拿取要求轻拿轻放,防止划伤 The product should be taken and put gently to prevent scratches;

②检出不良做好相关标识 do a good job of relevant identification of defective detection;

时间 Time:2020-12-18

地点 Location:Guangfeike

产品 Product:车灯 headlights

车型 Model:Jeep 新款指南者

数量 Quantity:3900台

作业内容 Work content: 查看车灯功能,并确认在5分钟内是否会有熄灭

Check the light function and make

①根据清单查到可疑批次车辆,打开车灯确认5分钟车灯是否会熄灭 Check the suspicious batch of vehicles according to the list, turn on the lights

to confirm whether the lights will go out in 5 minutes;

②完成的车辆将雨刮竖起,以便目视化管理 the completed vehicle will wiper upright, so as to facilitate visual management;

③完成后在清单上进行确认 Confirm on the list after completion;

时间 Time:2020-12-27

地点 Location:Guangfeike (Panyu, Guangdong)

产品 Product:显示器 Display

车型 Model:ES8

数量 Quantity:988台

作业内容 Work content: 显示器异响,通电检查

monitor abnormal sound, power check

①产品拿取要求轻拿轻放,不要触碰周边产品,防止产品碰伤 The product should be handled with care, do not touch the peripheral products,

to prevent product injury.

②检查出不良,做好不良标示后单独放置 check out the bad, do a good job after the bad mark placed separately;

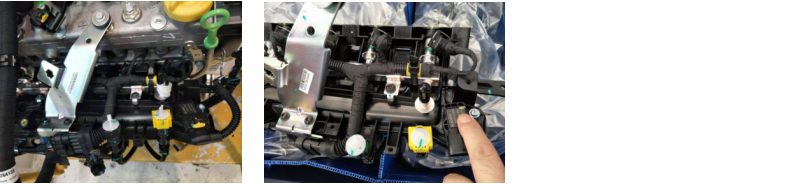

时间 Time:2020-11-27

产品 Product:进气歧管 intake manifold

数量 Quantity:3000台

地点 Location:长沙大众Changsha Volkswagen

车型 Model:途安 Touan

作业内容 Work content:进气歧管毛刺检验

intake manifold burr inspection

①打开箱子,需防止造成零件损伤 Open the box, to prevent damage to parts;

②对指定位置进行检查 Check the specified location;

时间 Time:2020-7-10

地点 Location:广菲克(长沙工厂) Guangfeike (Changsha)

产品 Product:降燥模块 dryness control module

车型 Model:K8 大指挥官

数量 Quantity:2010台

作业内容 Work content:降燥模块检验(烧板问题检测电压)

dry-reducing module inspection (burning board problem detection voltage)

①产品拿取要求轻拿轻放 Product take requirements light take light;

②产品取出后要放回原箱中,以便于零件追溯 After the product is taken out, it should be put back in the original box to facilitate

the traceability of parts;

时间 Time:2020-2-27

地点 Location:长沙大众 Changsha Volkswagen

产品 Product:齿轮 Gear

车型 Model:途安 Touan

数量 Quantity:8000台

作业内容 Work content: 检验齿轮孔径

Check the gear aperture

①产品拿取要求轻拿轻放,防止过程磕伤 The product is required to be taken and put gently to prevent the process of injury;

②产品检查过程中防止异物浸入 Product inspection process to prevent foreign matter immersion;

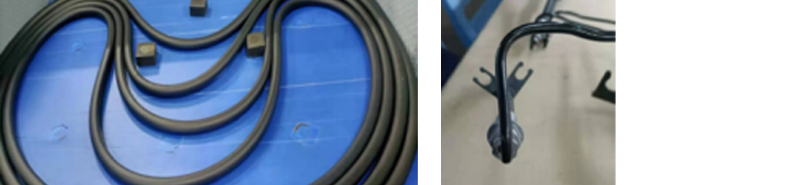

时间 Time:2019-10-27

产品 Product:胶条 Strip

数量 Quantity:5000台

地点 Location:上汽通用 SAIC GM

车型 Model:别克君越 Buick

作业内容 Work content:库博胶条检验外观是否变形 Check whether the appearance of the Cooper adhesive strip is deformed

①产品放置于检具,进行目视确认 The product is placed in the gage for visual confirmation;

②产品拿取要求轻拿轻放,防止产品碰伤 The product is required to take and put gently to prevent product bruise;

时间 Time:2020-6-7

地点 Location:广菲克(长沙工厂) Guangfeike (Changsha)

产品 Product:导航 Navigation

车型 Model:K8大指挥官

数量 Quantity:1600台

作业内容 Work content: 软件刷新 Software Refresh.

①产品拿取要求轻拿轻放 Product take requirements light take light;

②产品取出后要放回原箱中,以便于零件追溯 After the product is taken out, it should be put back in the original box to facilitate

the traceability of parts;

时间 Time:2020-10-21

产品 Product:GWM V2 多媒体主机 GWM V2 Multimedia Host

版本号 version :R7.41

数量 Quantity:224台

地点 Location:长城汽车(泰州高港)

零件号 Part number:7901102XNW01A

车型 Model:欧拉 ORA Smart

作业内容 Work content:软件刷新 Software Refresh

①主机上电,按空格发送开机命令,如果没有开机,检查pcan是否插反了,对调一下再试试,建议把两根线捆绑一起,一次插拔。

②输入reboot elk命令一定要在英文模式下输入,两个单词中间有一个空格,输入后直接回车进行刷机。

③建议按顺序依次刷写,这样主机也能依次重启,中间有没有刷写成功的先不要处理,下一轮刷写时直接断电等3秒再直接上电进行二次刷写,第一次刷写不成功的概率也很大。

④刷机完成后主机会自动重启,刷写完成后一定要进入工程模式看一遍版本信息,版本正确再进行测试!!!

⑤测试环节开机后先要进入工程模式检查版本信息!!!

⑥测试环节各个功能项不需要测试太长时间,功能正常即可。

⑦零件编号的尾号是79A和02A的主机是独立功放主机,89A主机和03A主机是集成功放主机,测试89A和03A主机时需要每次进行断电,否则会没有声音,79A和02A主机可以直接插拔。

客户 Customer:某空调厂

时间 Time: 6个月 6 months

地点 Location : 中国 China

团队 Team :2名审核员 2 Auditor

根据SAS审核问卷,现场进行供应商评估

On site supplier assessment based on Quality System Basics SAS Audit Questionnaire

评估供应商质量体系并确定目前状态与OEM期望之间的差距

Assess supplier quality system and identify gap between current state and OEM expectation

· 根据审核要求执行评估。根据要求标准确定并描述不符合项

Conduct Assessment based on Audit-requirements. Identify and describe nonconformities based on criteria of

requirements

· 开发行动计划并在纠正行动的实施中给予支持

Optionally develop Action Plans and support in implementation of Corrective Actions

· 按时发送并正确实施8D报告

· 8Dreports sent on time and correctly implemented

· 执行多次审核8+ Audits conducted

· 供应商批准行动计划,晓起在之后的操作中给予支持

· Action Plans approved by supplier and later implemented with PPIs support

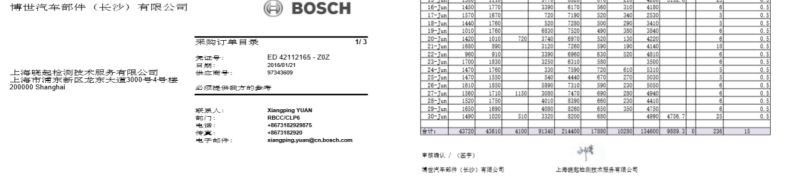

客户 Customer:发动机的1级汽车供应商 Engine

时间 Time: 6个月 6 months

地点 Location :宁波 Ning Bo

团队 Team :1名咨询师 1 consultant

客户供应商工厂生产过程质量监控及提升 Process quality control in supplier site

改进问题解决,减少客户抱怨 Improve problem solving,reduce customer complaint

· 顾客抱怨流程的优化完善

· To optimize and improve customer complain procedure

· 改善过程控制,更新过程控制方法

· Improve process control, upgrade process control method

· 完善现场可视化管理及措施有效性跟踪

· Improve visual management on site and trackingeffectiveness of measures

· 经验数据库的建立 Establish database

· 按时发送并正确实施8D报告

· 8Dreports sent on time and correctly implemented

· 减少了重复出现的质量问题,客户抱怨,质量故障成本和内部PPM

· Decreased repetitive quality issues, poor quality cost and internal PPM

· 完成质量意识培训和现场质量可视化管理

· Completed quality awareness training and quality visual management on site

· 建立或更新了过程控制程序和方法

· Set up or update process control procedure and method

客户 Customer:Tier 1 汽车供应商

供应商 Suppliers:共10多家供应商参加 10+ suppliers involved

地点 Location :杭州 Hangzhou

团队 Team :1名咨询师 1 consultant

2天的课堂培训,GP12介绍和早期生产问题解决

Two day’s classroom training,GP12 presentation and early production problem solving

在量产前的产品开发中的产品质量控制

Product quality control in new product development before SOP

· 培训给供应商质量人员、工程人员 Deliver training to APQP project team

· 主机厂和它的供应商一起参加培训,主机厂和供应商在一起沟通探讨,解决了主机厂和供应商正在实施GP12中的问题

· OEM and its supplier attended this training together, OEM and suppliers communicated and discussed

together, solved current problems that OEM and supplierimplement GP12

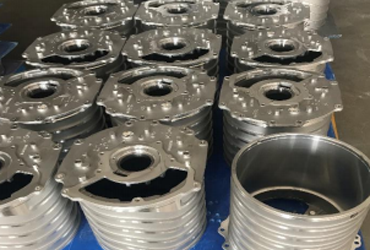

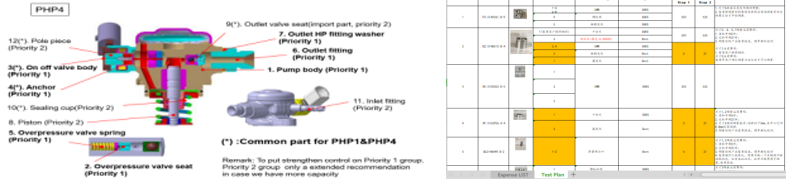

地点 Point:江苏太仓Taicang, jiangsu

产品 Product:电子 electronic

地点 Point:长沙 changsha

产品 Product:汽车发动机系统 Automobile engine system

时间 Time:2020-12-18

地点 Location:合肥&苏州&上海

产品 Product:汽车变速箱 automobile gearbox